Safe, Compliant Natural Gas Engineering Built for Real-World Operations

Natural gas infrastructure carries significant safety, regulatory, and operational responsibility, with planning and design decisions directly affecting long-term reliability and compliance. Tri-Mont supports natural gas projects with engineering grounded in real-world operating conditions—helping utilities and operators design, upgrade, and maintain systems that perform reliably under evolving regulatory requirements.

What Natural Gas Projects Must Address

Natural gas systems operate under intense safety, regulatory, and reliability expectations. Aging infrastructure, evolving codes, and increasing documentation requirements mean that decisions made during planning, design, and construction can have lasting consequences for system integrity and public safety.

Project teams are often required to manage challenges including:

- Increasing regulatory and documentation requirements

- Aging infrastructure and system modernization

- Risk reduction related to safety and overpressure events

- Complex coordination with utilities, agencies, and contractors

Addressing these challenges requires disciplined engineering informed by how natural gas systems are actually built, operated, and regulated. TRI-MONT supports natural gas projects from feasibility through operations, with a focus on safety, regulatory alignment, and long-term system reliability.

Natural Gas Capabilities

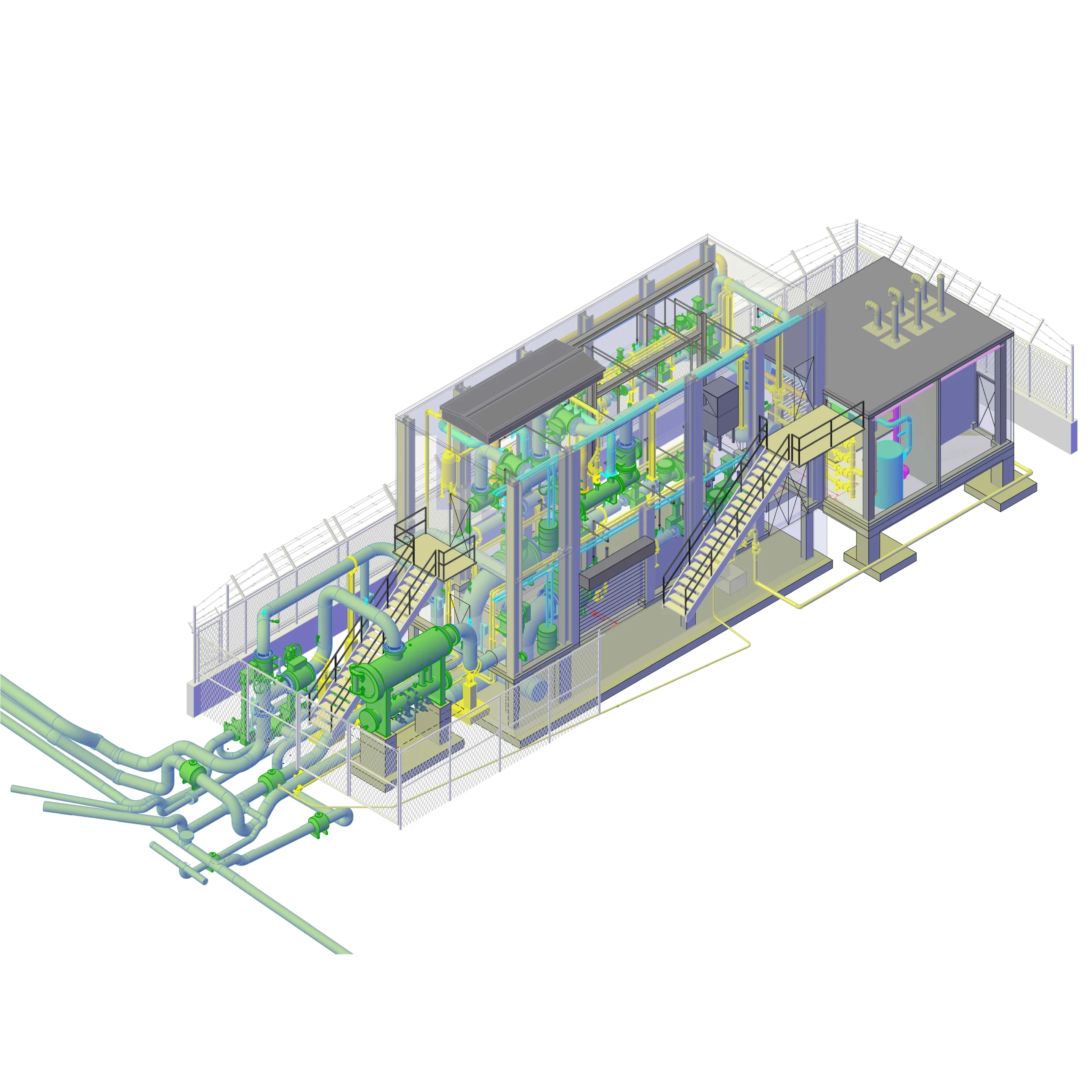

Station Engineering & Design

Regulator, gate, and district stations are critical control points for system safety and pressure stability. Station design must protect downstream systems, manage varying demand conditions, and meet stringent regulatory requirements.

Capabilities include:

- Conceptual and detailed station design

- Regulator sizing and configuration

- Overpressure protection and safety system design

- Civil, structural, and piping coordination

- Code compliance and constructability reviews

- Process Heating; including boilers, heat exchangers

- Building ventilation and electrical distribution

Transmission & Distribution Pipelines

Transmission and distribution systems require careful alignment of routing, materials, pressure design, and constructability to ensure long-term safety, resilience, and regulatory compliance.

Capabilities include:

- Pipeline routing and alignment

- Pipe sizing, material selection, and pressure design

- Valve, metering, and compressor station piping

- Road, rail, waterway crossings, and HDD

- Distribution system modeling and reinforcement

Construction Supervision

Construction activities introduce significant risk if work deviates from design intent or regulatory requirements. Operator-qualified supervision helps ensure systems are built safely, correctly, and in alignment with approved plans.

Capabilities include:

- On-site inspection and supervision

- QA/QC oversight

- Contractor coordination and field support

- Safety, testing, and commissioning support